Optimizing automotive performance - The key to monitoring machining center spindles.

Immerse yourself in the automotive world with our customer, a European leader generating impressive sales of €74.7 billion and selling nearly 3.5 million vehicles a year.

In the automotive industry, breakdowns are the production line's number one enemy, costing our customer €1,210,000 in losses per hour of unplanned downtime. hour of unplanned downtime. Faced with such high financial stakes, the need to prevent such incidents becomes paramount.

Find out why our customer chose to entrust this crucial mission to Monixo. Thanks to the accuracy of our diagnostics, we can provide provide unrivalled solutions for limiting costly incidents and maintaining optimum operational efficiency in the automotive industry.

Revolutionize your machining operations.

Our customer, despite sustained efforts in terms of scheduled maintenance, was faced with unexpected downtime, impacting production despite rigorous procedures.

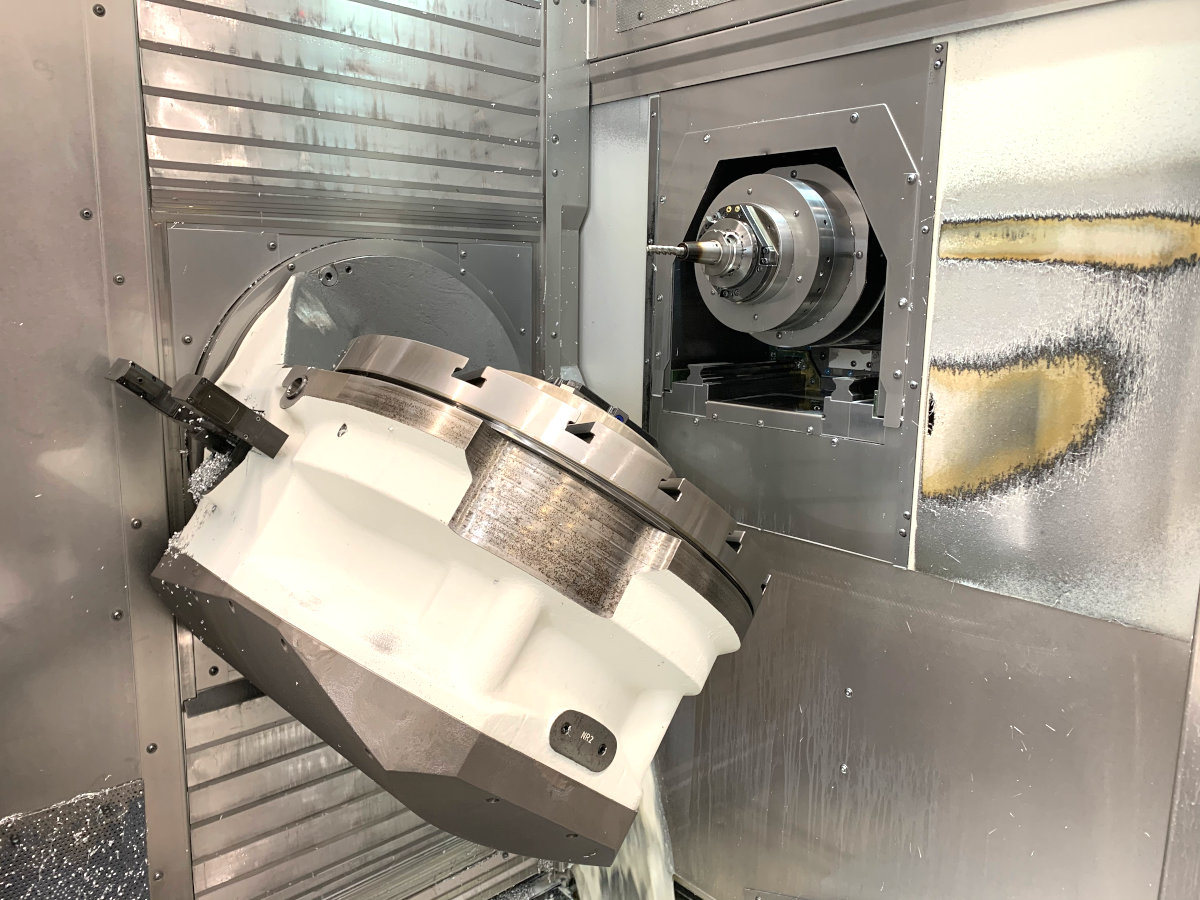

The aim is clear and ambitious: to improve the availability of machining centers by detecting axis failures and tool wear at an early stage, while optimizing scheduled maintenance to reduce planned downtime as far as possible. and tool wear, while optimizing scheduled maintenance to minimize planned downtime.

Although the data was collected and analyzed in-house, the correlation with outages remained elusive. Following a prolonged production stoppage, our customer opted for the Monixo solution. We intervene specifically to monitor the axis motors and spindles spindles, including the electro-spindle, a critical component in machine tools due to its cost and essential function.

La collaboration avec Monixo a transformé la fiabilité des machines-outils, se démarquant notamment par une prédiction précise de l'usure des broches. Les pannes et les arrêts de production qui en découlaient sont désormais évités, garantissant simultanément une qualité d'usinage exceptionnelle.

Innovation at the heart of data.

For precise anomaly detection, Monixo has pushed back the boundaries by meeting crucial needs:

- Evolution of collected data - From simple measurements of the overall vibration level to the provision of an FFT spectrum (spectrum, our technology is evolving to provide a detailed view of machining center performance. Pressure sensors are also used in innovative ways, adopting a measurement approach rather than "all-or-nothing" sensors.

- Sustained data collection - With the capacity to collect around 5 Gigabytes of data per day from each machining center Monixo has an abundant supply of data to feed its learning models. A wealth of data essential for in-depth analysis and precise detection of anomalies.

- Real-time storage and processing - We've revolutionized the approach by storing and processing data in real time, eliminating three-day storage delays. Faced with the unpredictable nature of some anomalies, our real-time monitoring offers unrivalled unrivalled responsiveness, enabling instant intervention in the event of shocks or collisions.

With Monixo, plunge into an era of innovation where anomaly detection becomes a precise science, bringing unrivalled reliability to every machining center. Redefine the standard with Monixo - your partner of excellence in industrial monitoring.

Reliable predictions for unrivalled performance.

In a remarkably short space of time, maintenance teams were able to exploit Monixo's fault predictions, orchestrating an optimal mobilization of resources for on-site maintenance. mobilization of resources for on-site maintenance. This partnership has brought about a major transformation in processes, introducing initiatives such as diagnostic support, a proactive approach, predictive maintenance plans, and much more. plans, and much more.

This revolution in maintenance organization has been the catalyst for a significant increase in plant availability. Explore the world of metalworking, where the spindle spindle occupies a central position, enduring tirelessly undergoing the stress and wear resulting from its intensive use. Discover how this essential component becomes the linchpin of performance, symbolizing the precision and endurance at the heart of the advanced machining process. machine tools. Monixo, your infallible partner, redefines the standards of predictive reliability, turning every challenge into an opportunity opportunity and raising industrial performance to new heights.