A digital ecosystem dedicated to industrial performance

Enabling you to monitor and anticipate the lifecycle of your machines, through relevant data, is our daily role.

Our commitment: to help build a more reliable, more efficient factory of the future.

We are

catalysts for their

industrial performance.

Feedback

Keep in touch

Questions & Answers

Our solutions are widely used in industrial sectors such as manufacturing, energy, aerospace, automotive, logistics and utilities, where equipment availability is crucial.

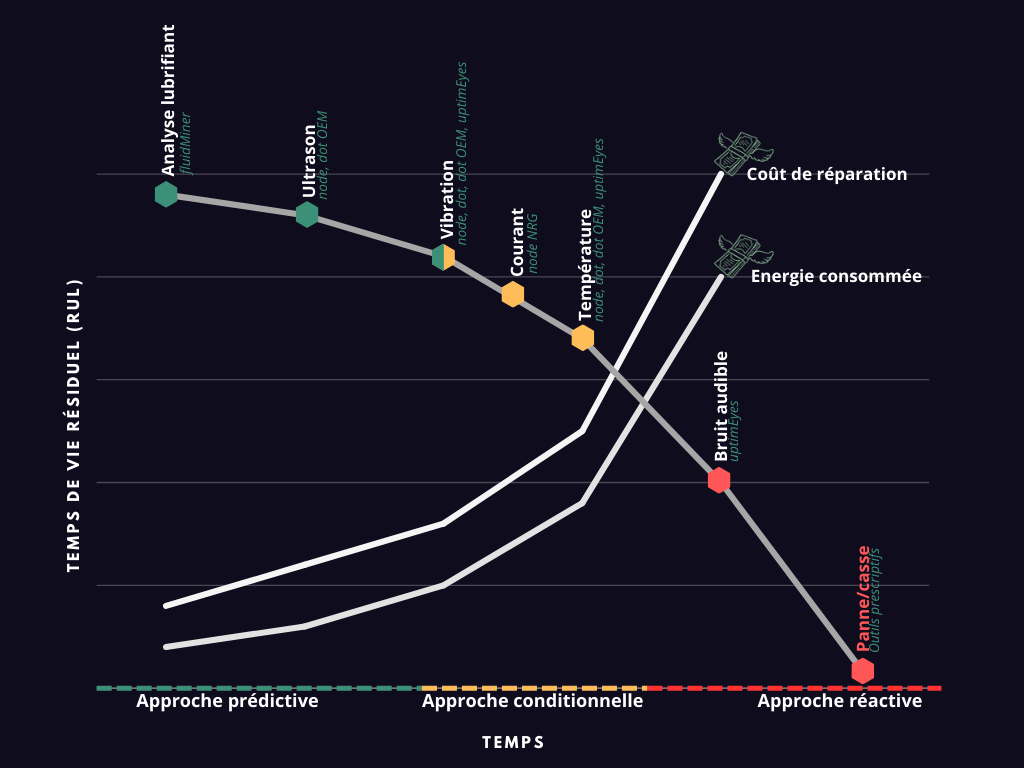

The data used can include measurements of vibration, temperature, pressure, electrical current, parts wear, as well as data from computerized maintenance management systems (CMMS) or maintenance histories.

Our data management policy means that data remains the property of our customers. Whatever the level of criticality of the data, we ensure that it is encrypted (dynamic encryption to reduce the risk of MITM attacks) and stored in a secure environment. The data is then processed to extract KPIs and recommendations for optimizing the use of our customers' machines.

Our solution is based on the use of sensors, data and algorithms to monitor industrial equipment in real time. It aims to predict potential failures and plan maintenance operations before serious problems arise.