Connected devices for real-time collection, analysis and optimization of energy consumption in industrial plants.

Use cases

Application Notes

Energy optimization

In just 4 steps, our solutionsoptimize the energy consumption of industrial production lines. This enables plants to improve their results, protect the environment, increase operational efficiency and improve reliability by reducing unplanned downtime.

Collecting data

They collect data from various sensors and meters throughout the industrial plant.

Generating a digital twin

This data is then used to create a digital model of the energy plant.

Identifying opportunities

The model is used to identify energy-saving opportunities.

Prescription generation

Recommendations are then generated to help implement these opportunities.

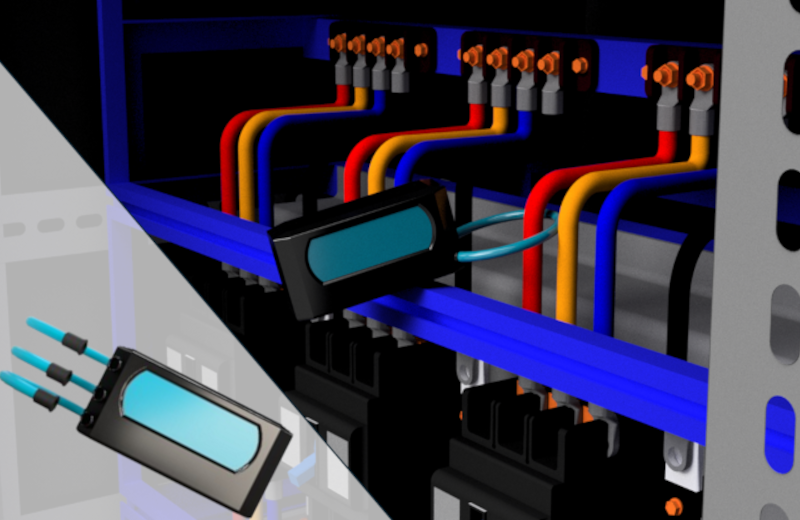

Computer vision for industrial performance.

UptimEyes optimizes production processes through automated inspection.