The Eye of Innovation.

Dive into the world of ophthalmic optics with the world leader, generating sales of €7.5 billion and deploying its expertise in the design, manufacture and marketing of corrective lenses and ophthalmic optical equipment. expertise in the design, manufacture and marketing of corrective lenses and ophthalmic optical equipment, with 69,000 employees in 81 countries.

In an industry where every second counts, the production of corrective lenses follows a meticulously orchestrated process, crucial to satisfying demanding customers who expect their orders the next day. to satisfy demanding customers who expect their orders the following day. The slightest breakdown can jeopardize this just-in-time flow, leading to unscheduled stoppages that disrupt the company's well-oiled schedule.

Our customer, aware of the stakes involved, aims to anticipate faults in its Air Handling Units (AHUs) in order to eliminate any unplanned downtime. Each interruption represents a major obstacle, compromising production quality and disrupting the meticulously organised supply chain. Preventive maintenance, though crucial, is hampered by the complexity of variable-frequency faults. variable frequency.

Discover how our predictive maintenance solution adapts to this variability, enabling proactive prevention of faults on CTAs. Be ready to redefine the way you produce in the ophthalmic industry, with smooth processes, seamless seamless production and optimum customer satisfaction. The future of predictive maintenance starts here.

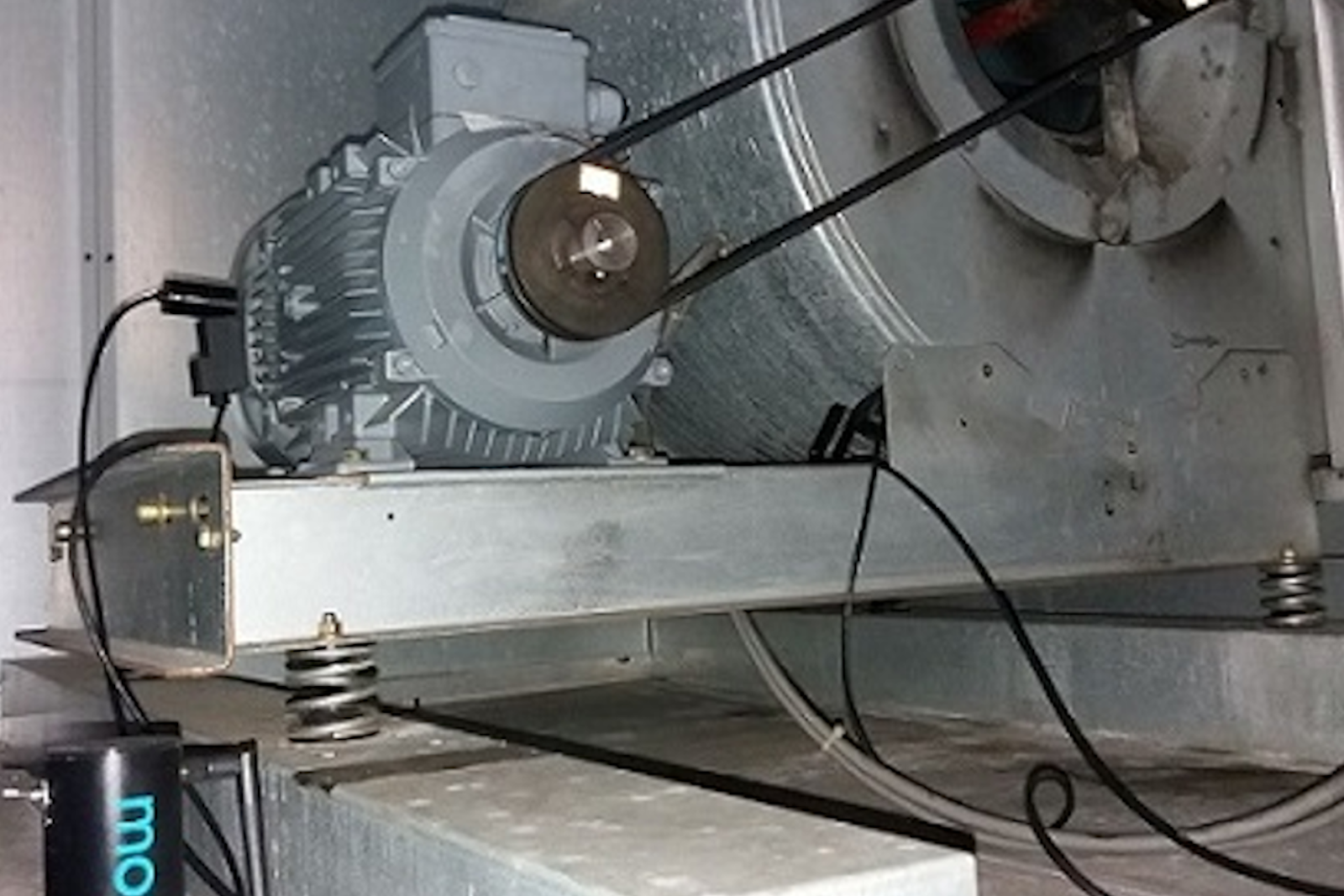

At the heart of the air handling unit.

In the complex anatomy of an Air Handling Unit (AHU), each organ plays a vital role, but none is as critical and delicate delicate as the belt. Responsible for essential transmission, it is also the most vulnerable link.

To ensure careful monitoring of wear, our approach focuses on :

- Strategic equipment - The installation of targeted sensors on key components interacting with the belt, such as the motor motor and transmission frame.

- Significant data - In-depth collection of vibration data (overall levels, spectrum) and temperature data, essential for the application of our learning models, for both organs under surveillance.

- Criticality management - Precise assessment of the criticality of interventions, enabling the customer to plan efficiently and define which parts are faulty. A pragmatic approach for seamless organization.

Discover how our solution, devoid of excessive artifice, provides a clear, pragmatic view of the health of critical organs within the AHU, ensuring uncompromising operational continuity and intelligent monitoring for unrivalled performance.

Uninterrupted operational continuity - Detect faults before they occur.

This proactive approach has paved the way for new processes, from diagnostic support to predictive maintenance plans, revolutionizing the global maintenance organization.

Key features of our solution :

Long-term predictions - Anticipate defects more than a month in advance, providing crucial leeway for optimal planning.

Zero undetected or unanticipated failures - Our technology ensures constant monitoring, eliminating any possibility of unplanned uninterrupted operational continuity.

An example of early detection of drive belt wear.